Excess flow check valves are safety devices that turn off the flow of fluid if the flow line or fitting on the outlet side of the valve tends to break or rupture. The excess flow check valves only close when the fluid’s flow through the valve is generating sufficient force to overcome the spring’s tension that holds it open. The valve is installed in the flow line to and from the pressure tank, as close to the tank as possible. All the valves have a specific closing flow rating that’s determined by the type of fluid that passes through them.

Working of an Excess Flow Check Valve

The valves are usually open valves, which always remain in the open position in ordinary operations. They allow the flow of liquid or vapour in either direction, but the flow checking is done only in one direction. The valve has an arrow that indicates the direction of the closing flow and when that direction’s flow exceeds the pre-determined rate, it automatically closes. The valve then remains closed till the pressure on both sides is almost equal. There’s a small bleed hole that allows pressure equalization, after which, the spring automatically reopens the valve. Due to the bleed hole, excess flow check valves don’t offer 100% shut-off.

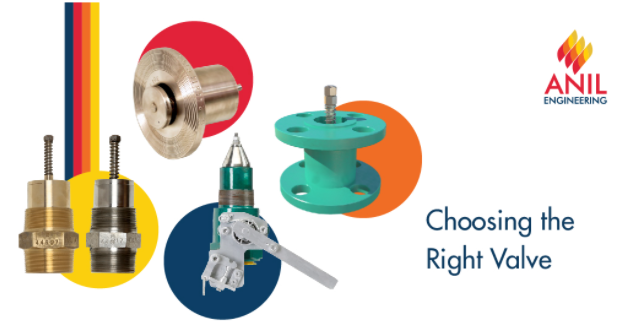

Choosing the Right Valve

The most critical aspect of the excess flow check valve is selecting the right closing flow rate. If the rating is high, the valve may not close when there’s a fitting rupture downstream. If the rating is low, the valve may close prematurely – in times of a pump startup when there’s a surge of fluid.

At Anil Engineering, we offer different types of Excess Flow Check Vales and believe that a spring that delivers a closing flow rate 50% greater than the expected flow will provide a sufficient margin for the valve to close in case of a serious event and also minimize nuisance closings.

Different Type of Excess Flow Check Valves:

Flange type Excess Flow Check Valves

The valve is designed to fit standard steel pipe flanges and helps to primarily control the flow of LPG and anhydrous ammonia during transport or storage. The valve fits perfectly into your steel-type flange and ensures safe operations with optimum performance. We can also deliver customized valves with different materials, closing flow settings and designs.

Internal type Excess Flow Check Valves

These are compact valves with just one-piece body construction and are designed for use with LPG as the main valve in pumping systems and in-line installations. They promise quick and easy installation and can fit in both half and full couplings. The valve can be opened manually by hand or with a pneumatic actuator.

Sandwich Wafer type Excess Flow Check Valves

The valves are suitable for corrosive environments and, hence, fit perfectly for multiple industrial applications. Sandwich Wafer Type Excess Flow Check Valves offer a robust metal body that can withstand extreme temperatures. They are available in a wide range of sizes and come with a mono flange connection to suit fluid applications.

Threaded type Excess Flow Check Valves

These valves are ideally best suited for low-pressure pipelines and help in controlling the flow of LPG and vapour transfer or equalization. The stainless-steel spring delivers consistent closing flow and long service life. You can choose valves in various range of sizes with threaded connections.

At Anil Engineering, we take pride in delivering high-quality excess flow check valves for multiple applications. Contact our expert teams to understand the best valve for your requirement.