Steam vaporizers use on-site available steam, other high-temperature gas or hot water as a source of heat to vaporize the liquid propane. Facilities that use steam for their processes also tend to have excess steam available in-house. As a result, using steam from a boiler or saturated process ensures efficient heat transfer along with precise temperature control. By delivering consistent pressure and combustion, steam vaporizers can promise a dependable and continuous gas supply for uninterrupted operations in your manufacturing, industrial or commercial spaces.

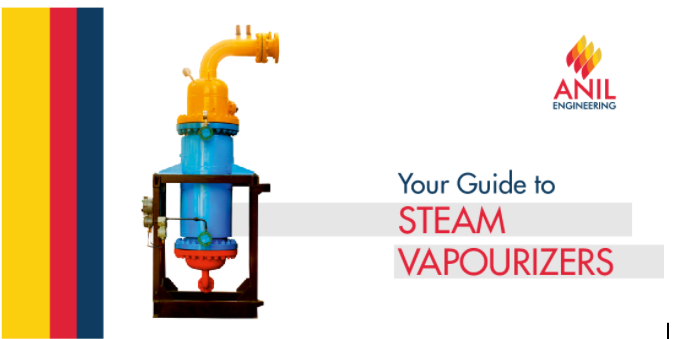

At Anil Engineering, we offer a comprehensive line-up of vertical steam vapourizers to vapourize liquid propane, LPG and butane in large volumes for robust commercial and industrial operations. Our most popular product – SX Pro is a steam heat exchanger with a capacity ranging from 500 kg/hr to 5000 kg/hr, making it ideal for big and small applications.

Key Features of Steam Vaporizers:

The steam heat exchanger utilizes saturated steam for vaporizing liquid LPG. The design for indirect heating is simple and reliable, offering 100% turndown.

AEPL vaporizers also ensure stress-free expansion and contraction of the heat exchanger tubes

The control system is designed in a way that the liquid inlet solenoid doesn’t open until the vapourizer reaches the minimum temperature

The Steam Vaporizer SX Pro is fully insulated for maximum thermal efficiency

Made with corrosion-resistant materials for a longer life

Compact design that fits easily in a small space with a wall-mounted boiler

Operates on all LPG mixtures – from 100% propane to 100% butane

Ideal for any climatic conditions

Benefits of Choosing a Steam Vaporizer:

- You don’t need to provide electricity or gas to operate the vaporizers

- The units have a small footprint, making them highly flexible for installations and implementation, without the need to expand your existing facilities

- Wide range of capacities to support a broad array of applications

- A reliable and economical source of LP-gas vapour

- Freestanding and skid-mounted units that are self-contained, pre-wired and pre-piped for instant connection with your propane/butane liquid inlet

- Highly compatible electrical supply and gas outlet for varied spaces

- Manufactured with global industry standards and codes in mind, ensuring complete safety

The Anil Engineering Advantage

We offer end-to-end services for steam vaporizers, along with complete customization. Our products are available to order with everything you need for seamless integration with your existing setup. Our solutions for design, engineering, testing, delivery and installation simplify the acquisition process and enable you to start using the vaporizers almost instantly. Backed by our expertise of 50+ years, our team can review your LPG requirements and offer consultation that accommodates your needs and your budgets. We can support the complete process of vaporization and even offer end-to-end post-sales guidance.

Our steam vaporizers are best suited for schools, universities, hospitals and clinics, hotels and resorts, office buildings, small factories, mines and excavations and more. The ideal start-up time is just 1 to 5 minutes, depending on the availability of the heating medium (i.e. hot water or steam).

Since India’s electricity production is largely thermal-based, it generates a high level of carbon footprint. By saving electricity using this steam vapourizer, you can even reduce cost and your carbon footprint. Ready to switch to SX Pro? Contact our pro team today!